Suspension systems are an integral part of mountain biking, and proper setup and regular maintenance will keep them working properly. Many novices use them incorrectly all the time, and there are many bad habits that can be picked up during suspension setup and maintenance.

1. The preload should be measured with the shock absorber unlocked

Some people may find this common sense trivial, but most of the time, no one cares about it. When you measure your suspension, it must be done with the suspension disengaged (full suspension open). If the shock is left in the "off" position, it won't give you an accurate reading, the reading will be low. When you're riding hills with the suspension wide open, the result is a fork or shock that's too soft. For this reason, even when you only have low speed compression, it's best to leave it on before taking measurements.

2. Preload is a very important factor, but not the only one

The first task is to get the sag on the shock set. If it is not set to 25% or 30% or less of what the car needs, it is a very bad start before tuning the suspension. In reality, preload is just the starting point for tuning your suspension, there are many other factors to consider. In theory, proper preload is critical. However, from a practical point of view, the measurement of preload is not so simple and clear. Proper body distribution on the bike is important when taking measurements because different riders have different techniques and positions.

For example, by moving forward or backward on the bike, crouching or standing upright, sitting or standing will give very different preload readings.

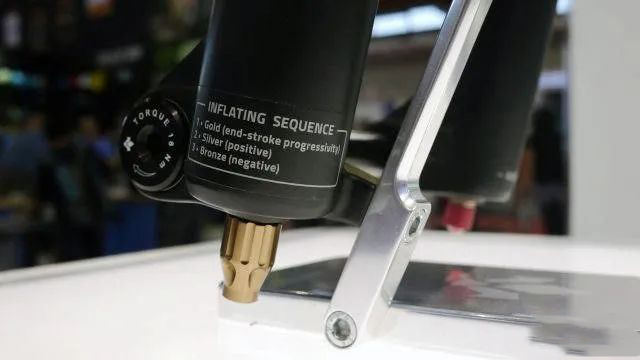

3. The air pressure in the negative air chamber cannot exceed the air pressure in the positive air chamber

Some forks have positive and negative air chambers that can be adjusted independently. A common mistake is to over-inflate the negative air chamber. Most forks use a knob to automatically balance positive and negative chamber air pressures. The effect of the negative air chamber is to resist the pressure of the positive air chamber. Without it, the fork will be jacked up. Therefore, adding air to a negative air chamber spring tends to compress the fork as it balances positive and negative air pressure.

The job of the negative air chamber is to make the fork softer and more comfortable to start with. The more you pressurize the negative air chamber, the more the suspension will do over small bumps, but it shouldn't be pressurized more than the positive air chamber.

If the pressure in the negative air chamber is too high, the fork will lose its travel. In this case, one would lean towards the stroke lever until the positive and negative air chambers reach the same pressure, but that means the fork stays shorter, loses travel and lowers the front end, which is obviously not ideal.

4. Do not use hard objects to deal with the dust between the inner tube and the dust seal

In the past, some people have suggested that, to get the fork in better shape, open the dust seal and put a little oil into it. Some people also use this trick to relieve the stress of getting stuck in their forks at high altitudes. The soft dust seals are now micro-grooved and easily damaged even with plastic straps without the risk of scratching the props with metal objects. Therefore, the best method is to simply dab the oil on the dust seal without scraping or breaking it.

5. Frequently clean the dust between the inner tube and the dust seal and do proper lubrication

External lubrication of the suspension surfaces is very important. After every wash of your bike, clean the outer tubes thoroughly and put a few drops of lubrication on the dust seals. Don't overuse it and wipe off the excess oil so it doesn't drip and stain the brake pads.

Three methods of lubrication

Protects the dust seal and forms a protective film, making it soft and efficient.

The oil is used to remove residual dust from the dust seals, creating a ring of oil mixed dirt on the pillars, which can be easily removed with a cloth.

Creates a lubricating layer on the strut to reduce sticking and penetrate into the dust seal that lubricates it.

So, not necessarily after every ride but at least after washing the bike, it is very important to clean the externally lubricated shock with a cloth and then use the cloth to remove excess lubricant.

6. Don't worry about the air chamber will leak after unscrewing the air nozzle

Many people believe that when the air barrel is unscrewed after inflating, the air leaks from the valve. To compensate for this, some people over-increase their air pressure.

Actually it is the opposite. If the pump and valve are working properly, when the pump ring nut is unscrewed, the valve closes before the air is released. The pump o-ring remains in place until the valve closes, then allows air to escape. So, the run flat sound we hear is just the air contained in the hoses and pump gauges, so...not air from the shock. Instead, when you attach the pump to the shock, a portion of the air contained in the shock's air chamber escapes to fill the tube and pump gauge. Air loss depends on the size of the air chamber.

Therefore, the pressure loss we measure is only meaningful when the gas cylinder is connected to the valve. When we unscrew the gas cylinder, the pressure is exactly the pressure measured by the pressure gauge.

7. Pay attention to regular maintenance of shock absorbers

The last "secret" is nothing more than simply following the manufacturer's instructions, as long as the suspension product is functioning properly, it should be maintained regularly. Suspensions are complex and delicate components, and if they are always cleaned regularly, they will always be in top condition.